Circular Systems in Practice

Photo Credit: Hollyharryoz

Circular Systems — what does it actually mean?

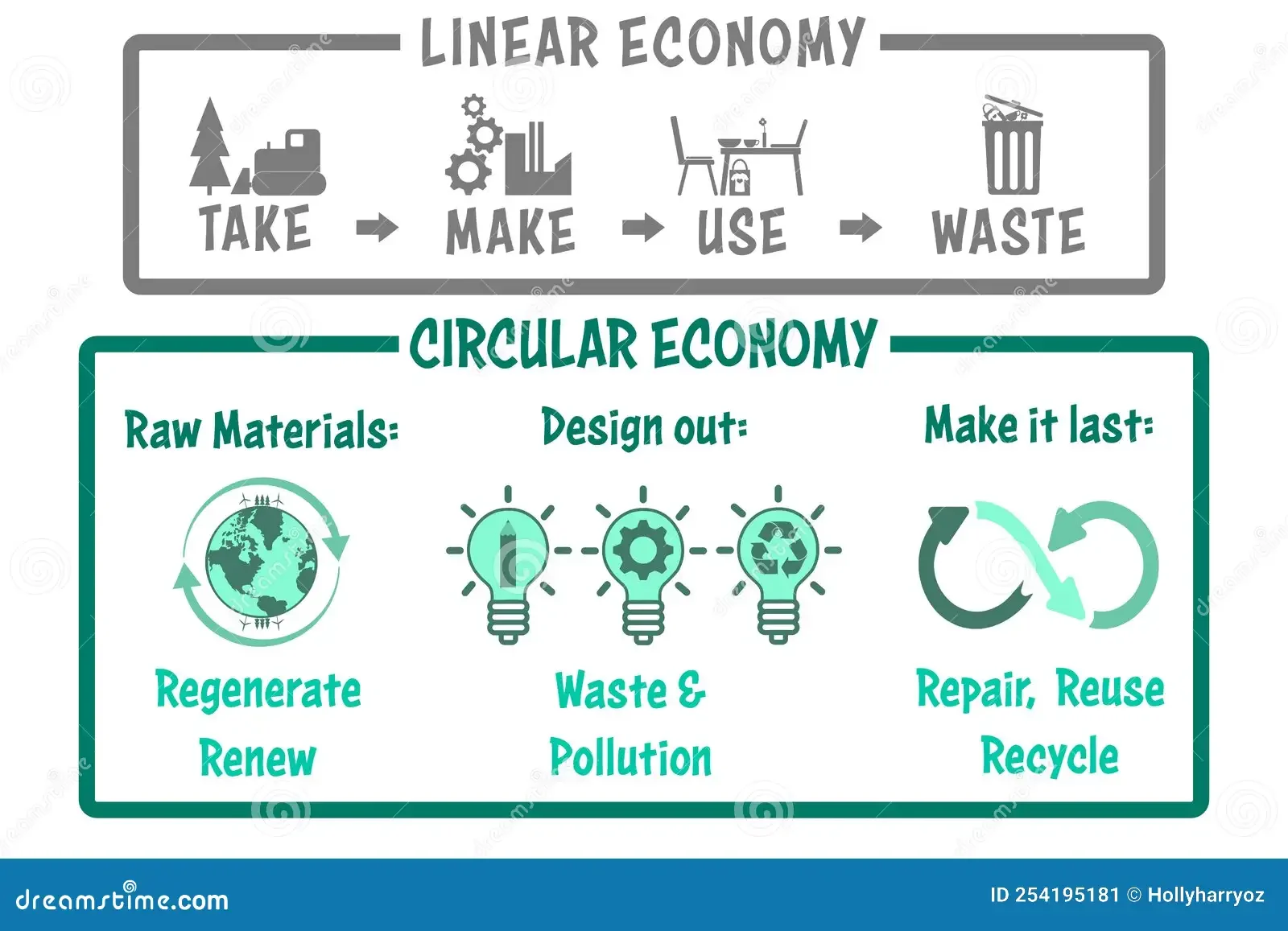

Circular systems reimagine how we design, use, and reuse resources. Instead of the old “take–make–waste” approach, they keep materials in play for as long as possible, regenerate natural systems, and create new value from what would otherwise be discarded.

Think of it as building loops instead of lines: products are designed to last, waste becomes a resource, and industries collaborate to make efficiency and regeneration the norm.

In this context Circular systems are not abstract theories – they’re being engineered now, across industries from mining to construction, companies and engineers are turning circular economy principles into real projects and infrastructure.

This edition explores how circular systems engineering is applied beyond theory, and what this transition means across industry sectors like mining.

It also highlights why engineering innovation must sit at the heart of policy if we are to achieve a vision of full circularity by 2040.

Mining and Minerals: Closing the Loop from Mine to Tailings and Back

The mining sector provides the raw materials for our economy, but it’s also now embracing circular practices to keep those materials in circulation.

The mining industry is actually well-positioned to adopt such strategies, not only to reduce waste but to create new value from what was once discarded.

For example, miners are increasingly looking at ways to reprocess tailings (the waste from ore processing) to extract additional minerals or even develop new products from them. This means the traditional “extract–use–dispose” model is giving way to “extract–use–recover-reuse”, where mine waste can become a valuable resource.

One cutting-edge example is in critical minerals processing. Australian innovators recently developed a novel molten sulphur process to recover valuable metals from used lithium-ion batteries (the so-called black mass from spent EV batteries).

Through an accelerated engineering program, the team at Scimita in partnership with Oxleigh Technologies (OT) evaluated all possible pathways and landed on this breakthrough process.

The technology has passed proof-of-science and is now in pilot stage, showing promising recovery rates and cost competitiveness. Remarkably, beyond just recycling batteries, this molten sulphur reactor approach could be applied in mineral processing for lithium, nickel, cobalt and other critical metals.

In essence, the same innovation that recovers metals from used batteries might help mining operations extract metals more efficiently from ores or waste, closing the loop from mining across to the consumer.

Such initiatives are not just theoretical – they are being recognised and funded. It is a proud moment for me to see the work by the team at Scimita on the molten sulphur process has earned two Cooperative Research Centres Projects (CRC-P) grants, underscoring its alignment with national innovation priorities.

One vision arising from this is the development of mobile “micro-smelters” that could be deployed at mine sites or recycling facilities. These would locally process materials and recover metals on-site, rather than shipping everything to giant centralised smelters.

If successful, this could allow countries like Australia to add significantly more value locally across the mining value chain – from mine, to mill, to recovered material – instead of losing that value when exporting raw ores. In a fully circular mineral economy, a metal might be mined, used in a product, then recovered and looped back into the supply chain repeatedly, with minimal new extraction needed.

The example above, and others we will share in future editions across sectors of energy, manufacturing, construction, infrastructure, and regional developments, make it clear that circular systems are already being engineered across diverse sectors.

What was once an abstract concept is now tangible projects: from mines that treat their waste as a new resource, to factories that upcycle old materials, to buildings designed to live multiple lives. The transition to a circular economy is underway, but accelerating it will require all hands on deck – innovative engineers, forward-thinking businesses, supportive policymakers, and engaged communities.

We invite you to connect and join this conversation about circular innovation. Whether you’re an engineer, a policy maker, a student, or an industry leader, your perspective is valuable in shaping the solutions that will get us to full circularity by 2040.

This edition is just a teaser of what’s happening on the ground. In upcoming editions, we will dive deeper into how these circular initiatives progress and how you can be involved.